What makes up the price of a Zara hoody

David Hachfeld, 20. November 2019

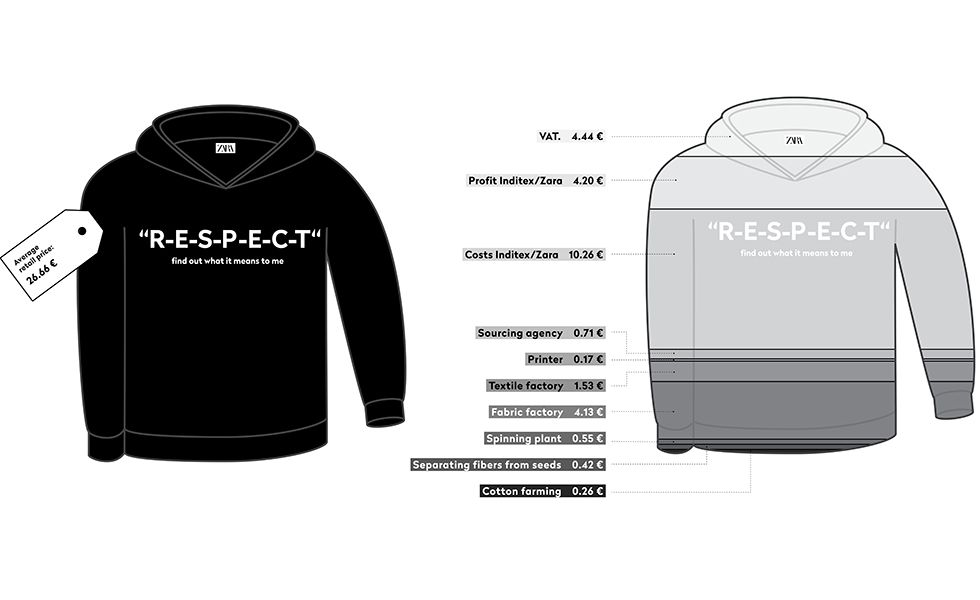

A lot of work goes into producing an item of clothing. But how are these efforts remunerated? How much of the retail price of a piece of clothing goes to the workers, and how much do companies make in profit? To find out, we persistently demanded information from Zara on its ‘Respect’ hoody, went to Izmir in Turkey in search of clues – and we also analysed dozens of financial reports, trading data and further sources, and spoke to experts. We used our findings as a basis to produce detailed estimates on how the costs of the ‘Respect’ hoody are distributed throughout the supply chain – and who earns how much at each stage. In this case, ‘we’ refers to Public Eye together with the Schone Kleren Campagne and the Collectif Éthique sur l’étiquette, our Dutch and French partner organisations within the Clean Clothes Campaign network, and the Paris-based research group Le Basic, whose team did the calculations.

©

Timmy Memeti

©

Timmy Memeti

One sweater, many prices

Zara’s parent company Inditex is well known for its unique, centralised supply chain: items of clothing are designed and commissioned in its headquarters in A Coruña, Spain, then produced in a range of countries before being shipped, driven or flown to Spain, where they are sold online and distributed to branches and shipping centres. However, the retail price of the clothing varies significantly from one country to another. In Spain the price of the hoody we examined was 25.95 euros, in France and Germany it was slightly more expensive at 29.95 euros* – and significantly more expensive in Switzerland: CHF 45.90 (39.57 euros). Since June, Zara has sold the hoody at a roughly 50% discount and finally, the remaining hoodies (likely only a few) were sold in branches in Zurich for only CHF 12.95 (11.19 euros).

The difference in prices is in part due to different VAT rates, and varying retail and online retail costs. More significantly however, it seems that prices are linked to consumer expectations and purchasing power. While in Spain, Zara positions itself as a mainstream, affordable brand, in Switzerland it is positioned as a more glamorous, mid-range brand. We took account of the different prices and discounts in our calculations, and we also factored in different VAT rates. Markets with high prices such as Switzerland featured less significantly in our calculations because other markets, like Zara’s home market Spain and large EU countries, account for more revenue. Using this basis, we estimated that the average retail price that Zara actually charges per hoody is 22.22 euros (before VAT). But how much did Zara itself pay per hoody?

How much did Zara pay?

Zara didn’t want to answer this question, so we worked it out for ourselves. We found that the approx. 20,000 Respect hoodies produced had been sewn and printed in Turkey in 2018. We found that Zara does not commission production of the hoodies itself; the role of sourcing agency is played by another company, which commissions the various production steps to other companies. We estimate that Inditex paid the agency CHF 7.76 euros per hoody. To come up with this estimate, we took comparable offers from other Turkish companies, asked experts and compared the data with our calculations for the cost of materials and processing.

Our estimated production price is approx. 25% lower than the comparable offer we received for a fictitious company, which seems realistic given the company’s strong purchasing power: Inditex is one of the largest buyers of clothing produced in Turkey. We analysed the financial statements from the past five years of the agency commissioned by Zara and used this as a basis to estimate that, of the CHF 7.76 euros, the agency kept 21 cents of profit and 49 cents to cover its costs and service debt. This is a conservative estimate – during our field research we heard that the agency earns one to two euros per hoody.

Far from living wages

Inditex assures us that the purchase prices it pays are high enough. But how much goes to the sub-contractors? According to our information, for the processes of cutting the material, sewing, packing and attaching the labels, the factory in charge was only paid nine Turkish lira (1.53 euros). Production is split into numerous individual steps; the hoody makes its way through many hands and machines. In total, it takes some 30 minutes of work to produce a single hoody – this estimate has been approved by various experts. In our research, we hear about factory worker wages of 2,000 – 2,500 Turkish lira (310 – 387 euros), which is the statutory minimum wage or just over. For a net monthly wage of 387 euros the factory would have to calculate a gross hourly wage of at least 2.44 euros, i.e. 1.22 euros for 30 minutes. By way of comparison: in order for workers to receive a living wage according to the Clean Clothes Campaign Turkey’s estimate, they would need to receive a gross hourly wage of 6.19 euros, or CHF 3.10 for 30 minutes.

The workers who make the Respect hoody don’t make anything near a living wage.

If the factory is only being paid 1.53 euros – from which, in addition to salaries, it has to pay the operating costs of maintaining the buildings and machines, electricity costs or management salaries – it doesn’t take long to realise that it’s going to be more than tight. On the basis of our calculations, we assume that the factory had to pay 1.10 euros per hoody in the form of wage costs, leaving only 43 cents to purchase necessary trims, cover the factory’s operating costs and if possible to make some profit, which is of course what the factory owners want. It’s clear that the workers who make the Respect hoody don’t make anything near a living wage.

A few cents for printing

Just a half a lira, so approx. 9 cents, might have gone to the printing company for each print. This figure was given to us during our field research, and it was confirmed by a local industry expert. Given that two prints are needed – one for the front and one for the back – we estimated the printing costs at 17 cents per hoody, half of that for salaries. This sum is also so low that little would be left over after production, even if workers are only paid the minimum wage. With margins like these, there is a high risk that labour costs come under even further pressure: for instance from higher performance requirements (fewer seconds for each step of the process), underpaid or unpaid overtime or the use of day labourers.

According to our research, Zara also bought the fabric through an agency. We estimate fabric costs at 5.35 euros per hoody. Once again, we looked at comparable offers, and we estimated that due to its dominant market position, Inditex and/or its agency was able to negotiate the price down by 10% compared to the offer we received for a smaller, unknown company.

From field to fabric

We wanted to investigate more than just the labour costs of producing the hoodies, so we also analysed the production of the fabric. We estimate that some 1.7m2 of material is needed for each hoody. Experts tell us that the fabric is a blend of French Terry with a brushed back side; the fabric has a density of 260 grams per m2. The label states that it is 84% cotton, which Inditex states is organic. According to information provided by the company, the raw cotton is processed in India. We estimate that the cotton farmer (in India cotton farming is primarily carried out by small-scale farmers and is labour-intensive) was paid around 26 cents for the quantity of raw cotton required to produce one hoody. Once you deduct 5 cents for seeds, irrigation and further inputs, a total of 21 cents is leftover to pay labourers and the farmer. Around three times this amount would be needed to pay the labourers a living wage.

Cotton is usually processed from raw cotton to cotton lint, yarn and finally fabric in highly mechanised processes and in large quantities. Therefore the labour costs of these steps of the process are low. The profit margins at these steps are also low; based on our analysis of financial statements and other industry data, we estimate these to be 28 cents per hoody. Companies likely make this commercially viable on the basis of quantity rather than margins.

©

Timmy Memeti

©

Timmy Memeti

Zara’s profit

As an interim conclusion we can state that, according to our estimates, from cotton field to printing, the total cost of earnings and salaries for each hoody is 2.08 euros. We estimate that Zara pays its Turkish sourcing agency 7.76 euros per hoody. Then the hoody must get to the shops and be sold. We estimate the freight costs at 41 cents (we assume that the hoodies are transported from Turkey to Spain by container ship and then by lorry to the logistic centre in Zaragoza). In the 2018 financial year, Inditex’s gross profit margin (revenue minus purchase expenses) was 14.8 billion euros, namely 56.7% of revenue. The margin on the hoody was slightly higher at 63%. We used this basis to apply the average cost and profit shares to our hoody.

We estimate that for each hoody, 3.92 euros goes on staffing costs (primarily at the point of sale) and 5.93 euros on store rents, amortisation and further operating costs. If money went to the copyright holder Universal Music for the printing of Aretha Franklin’s lyrics, then these would come under the last category. What is left over? According to our estimates each hoody generates 4.20 euros in profit – more than double the amount that goes to all the workers involved in the production process. After tax, a net profit of CHF 3.27 remains.

‘Respect’ requires redistribution

Zara’s business model is geared towards maximising profit: a return on sales target of over 15% and shapes relationships in the supply chain. Are there other ways? What if fair wages were paid from cotton field workers to textile factories, to the shops? To increase wages in Turkey and India to living wages, they would have to be raised by a multiple of between 1.9 and 3.0 at each step of the production process. And yet the difference in price per hoody would be just 3.62 euros, slightly less than Inditex itself earns from each item. If each of the companies in the supply chain gave up part of their profits, the room for manoeuvre would be even greater. If Inditex had the will, it would be possible to pay living wages without this automatically increasing the retail price. Utopian? It might seem so today. Possible? Absolutely.

If Inditex had the will, it would be possible to pay living wages

For us, ‘Respect’ in the fashion industry means that everyone involved in producing the raw materials, making the fabric or sewing the garments can live properly from their wages – and that those who control the supply chain don’t abuse their power to drive down prices. The distribution of power and profit within the supply chain needs to be challenged, re-negotiated and if necessary strikes in favour of better wages and producer prices must be held. In addition, people need to show solidarity and break out of their role as passive consumers. They need to make it clear that respecting the human right to a living wage it cannot be a question of perspective – it must be respected.

* Exchange rate applied:

- CHF-EUR: 0.86; USD-EUR: 0.85; EUR-INR: 80.74 (yearly average exchange rate 2018).

- For production costs and living wage estimates in Turkish lira: CHF-TRY: 5.19; EUR-TRY: 5.87 (monthly average exchange rate December 2018).

- For current salary estimates in Turkish lira: CHF-TRY: 5.58; EUR-TRY: 6.46 (monthly average exchange rate September 2019).

**************************

This version is a translation of a text which was written in German. In case of discrepancy between the different versions, the original German text will prevail.